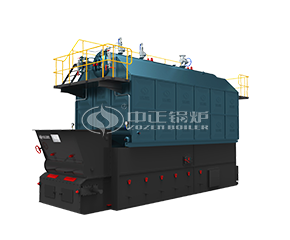

ZOZEN Boiler Company provided two 25-ton coal-fired steam boilers to a paper mill in Indonesia. This series of boilers can provide high dryness steam, reducing heat transfer losses during the process.

Steam is mainly used for heating and drying pulp, effectively removing moisture from the paper-making process, which is key to ensuring paper quality and production efficiency. High-quality steam also means better heat transfer efficiency, directly improving the energy utilization rate in the production process.

The chain grate structure facilitates uniform fuel distribution and continuous combustion by moving the fuel evenly into the furnace with a continuous moving chain. This uniform combustion ensures the stable release of thermal energy, improving the efficiency of heat exchange.

.jpg)