Case introduction

I. Project Background:

PT Pakan Sehat Unggul (PT PSU) is a well-known Indonesian enterprise specializing in animal feed and livestock products. In the animal feed industry, steam is not only essential for sterilizing, cooking, and mixing raw materials, but also directly influences product quality and production efficiency. Therefore, a reliable, efficient, and environmentally friendly steam supply system is crucial for PT PSU.

During the feed production process, the demand for steam is stable and continuous. At the same time, the company aims to fully utilize local biomass resources, such as palm shells, to reduce energy costs and achieve green production. As a widely available agricultural by-product in Indonesia, palm shells offer high calorific value and low ash content. However, their combustion characteristics place higher requirements on the boiler’s combustion system and grate structure.

II. Solutions:

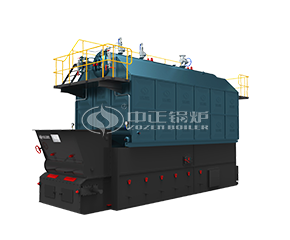

To meet PT PSU’s specific needs, ZOZEN Boiler tailored the SZL10-1.25-SS biomass steam boiler, specially optimized for burning palm shells. This boiler series adopts a horizontal double-drum, longitudinal arrangement structure, and is equipped with an advanced chain grate and high-efficiency combustion system. The grate is reasonably designed to ensure uniform fuel distribution and complete combustion, effectively reducing slagging and jamming.

With a thermal efficiency of over 86%, the SZL series palm shell biomass steam boiler achieves full combustion and maintains low carbon content in ash, providing PT PSU with a reliable, cost-effective, and environmentally friendly steam supply solution.

.jpg)