Case introduction

The textile industry relies heavily on energy, requiring a continuous supply of high-temperature steam for processes like yarn treatment, dyeing, and finishing to ensure steady production and consistent quality. As a key supplier to international fashion brands, Kohinoor Mills in Pakistan produces over 100 million meters of fabric annually and demands steam systems that are reliable, environmentally friendly, and cost-effective.

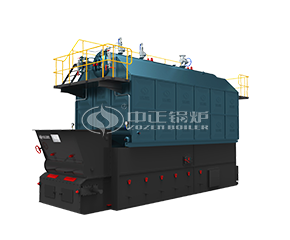

To address the issues of pollution and high operating costs from traditional coal-fired boilers, Kohinoor Mills selected ZOZEN’s DZW series 20-ton biomass reciprocating grate steam boiler. This upgrade enables the use of biomass fuels, supporting a shift toward cleaner, sustainable energy.

Solution Highlights:

The DZW series boiler is highly flexible, able to utilize various fuels such as bulk biomass, construction waste, wood chips, and palm shells, helping Kohinoor Mills reduce fuel expenses and make better use of available resources.

Its innovative reciprocating grate and independent air chamber design ensure thorough combustion, even when burning high-moisture fuels, reducing ash buildup and improving operational stability.

.jpg)