Case introduction

In palm oil production, the steam boiler is a vital energy source, supplying substantial heat for key processes such as steaming and refining. AEN PALM OIL PROCESSING (PVT) LTD., a leading palm oil producer in Sri Lanka, supplies raw materials to renowned international brands including McDonald’s, Colgate, Fanta, and Chanel. Embracing a commitment to green and sustainable development, AEN PALM OIL PROCESSING chose to use waste palm fiber as boiler fuel.

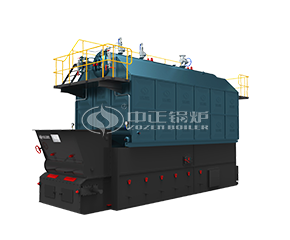

With the introduction of ZOZEN’s third-generation 15 tph biomass-fired reciprocating grate steam boiler, the company successfully addressed the common coking issue associated with palm fiber combustion, leading to a fruitful partnership with ZOZEN.

The ZOZEN DZW series biomass-fired boiler is a tri-drum water tube boiler known for its low ash accumulation, high efficiency, and excellent environmental performance. It allows for continuous operation without shutdowns for ash removal. To tackle the unique combustion characteristics of palm fiber, ZOZEN engineers optimized the feeding hopper, furnace arch, and air distribution, effectively controlling coking. Additionally, the boiler features an inclined reciprocating grate, enhancing fuel adaptability and ensuring thorough combustion of palm fiber, which helps reduce fuel costs.

Under the guidance of ZOZEN engineers, the boiler has been fully installed and commissioned on-site and is now operating steadily and reliably.

.jpg)