Case introduction

recision Steam Solutions for Paper Production

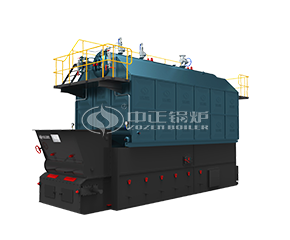

In paper manufacturing operations, steam quality directly impacts both production efficiency and end-product quality. ZOZEN Boiler’s WNS series gas steam boilers are engineered specifically to meet these critical industrial requirements. Our advanced three-pass design with optimized large furnace construction consistently generates high-quality, low-moisture steam – essential for superior paper manufacturing performance.

Venezuelan Paper Mill Success Story

ZOZEN recently commissioned a WNS series 6 tph three-pass gas steam boiler at a major Venezuelan paper production facility. The boiler’s exceptional performance has delivered measurable improvements across key operational metrics:

● Enhanced drying and pressing efficiency

● Reduced processing cycle times

● Improved paper smoothness and tensile strength

● Significant energy consumption reductions

Technical Advantages for Paper Manufacturers

The WNS series provides paper mills with distinct competitive advantages:

1.Production Efficiency – Low-moisture steam enables faster drying, increasing line speeds and overall capacity

2.Product Quality – Consistent steam characteristics ensure uniform paper thickness and superior surface finish

3.Energy Optimization – Advanced thermal design minimizes fuel requirements while maintaining output

.jpg)