Q: What does”types of biomass boilers”actually include?

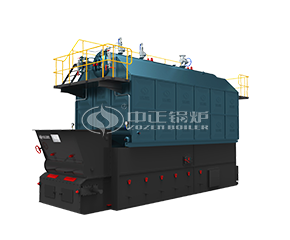

A: The types of biomass boilers span designs, combustion systems, and heat media used to turn solid biomass into steam or high-temperature heat. In ZOZEN Boiler’s portfolio, this includes chain-grate water-tube steam/hot-water units and thermal oil heaters tailored to different fuels, capacities, and site conditions—so you can match the boiler to real operating needs.

Q: Which types of biomass boilers does ZOZEN Boiler offer?

A: ZOZEN Boiler’s core lines cover most industrial scenarios:

– DZL series: Compact, quick-install chain-grate, ideal for small to medium loads.

– SZL series: Double-drum chain-grate with larger heating surfaces for higher capacities and wide fuel adaptability.

– DZW series: Three-drum, reciprocating grate for variable fuels, longer residence time, and anti-coking performance.

– YLW series: Biomass-fired thermal oil heater delivering 320°C heat at low pressure. These represent the most commonly applied types of biomass boilers in industry.

Q: How do I choose among the types of biomass boilers?

A: Start with fuel form and stability (pellets/wood chips vs. mixed agro-residues), required output and pressure/temperature, steam vs. thermal oil, emissions limits, site constraints (height, footprint, lifting), and service availability. ZOZEN Boiler engineers help map these criteria to the right types of biomass boilers for the lowest lifecycle cost.

Q: What efficiency features distinguish ZOZEN’s types of biomass boilers?

A: Optimized furnace volumes, staged air, and precise grate control promote complete combustion. Economizers and air preheaters recover heat; membrane water walls and enhanced surfaces raise transfer efficiency. Across types of biomass boilers, these measures translate into lower fuel consumption per ton of steam.

Q: What about operation, maintenance, and total cost?

A: Automated ash handling, soot blowing, and accessible layouts reduce manual work and downtime. Robust grates and standardized components simplify servicing. Selecting the correct types of biomass boilers for your fuel and duty maximizes availability and minimizes the steam cost over the equipment life.

Q: Which industries benefit most?

A: Textiles, food and beverage, paper and packaging, chemicals, building materials, agriculture processing (rice, palm, sugar/bagasse), and district heating commonly adopt ZOZEN Boiler’s solutions.

For projects in Singapore, contact Singtech Boiler—ZOZEN Boiler‘s authorized local partner—for pre-sales consulting, compliance guidance, system design, logistics, turnkey installation/commissioning, operator training, rapid spare parts, and 24/7 after-sales support. Singtech Boiler makes it easy to compare the types of biomass boilers and select a ZOZEN solution that delivers efficiency, reliability, and sustainability.