Q: What is a boiler for dyeing and why does it matter?

A: A boiler for dyeing is the thermal backbone of dyeing, bleaching, rinsing, printing, drying, scouring, and heat-setting. Whether you need saturated steam or high-temperature thermal oil, a well-matched boiler for dyeing delivers stable temperature, pressure, and flow, directly impacting fabric quality, color consistency, production speed, and energy costs.

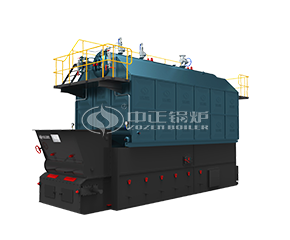

Q: Which solutions from ZOZEN Boiler are best as a boiler for dyeing?

A: ZOZEN Boiler offers a comprehensive portfolio to cover the full spectrum of textile processes:

– Gas-fired steam boilers: WNS series, SZS series, and ZZ series. These are clean, efficient choices for core steam needs.

– Thermal oil heaters: YQW series, YQL series, YLW series for 320°C process heat at low pressure—ideal for stenter heat-setting, print curing, dyeing machine preheating, and drying lines.

– Biomass-fired steam boilers: SZL, DZL, DHL, SHL series for plants pursuing renewable fuel and cost control, with strong adaptability to pellets, wood chips, palm shells, rice husk, and more.

– Coal and circulating fluidized bed options are also available where permitted and advantageous.

Q: Why choose a gas-fired steam boiler for dyeing lines?

A: As a boiler for dyeing, gas-fired steam delivers clean combustion, fast response, and stable output. ZOZEN Boiler’s WNS uses a full corrugated furnace and three-pass design with optional condensing economizer for high efficiency—up to 98%. The SZS D-type water-tube design suits higher pressure, larger capacities, and superior steam quality. The ZZ series serves medium-temperature/medium-pressure needs. Low-NOx configurations can reach 30 mg/Nm³, supporting stringent environmental compliance.

Q: When is a thermal oil boiler for dyeing the better choice?

A: If the process demands precise, uniform high temperatures without steam-system complexity, a thermal oil boiler for dyeing is ideal. ZOZEN Boiler’s YQW/YQL/YLW series provides stable 320°C heat at low pressure for stenters, laminators, dryers, dyeing machine preheating, and print heat-fixation, reducing heat loss from steam traps and improving temperature control.

Q: Can a biomass boiler for dyeing cut costs and carbon?

A: Yes. A biomass boiler for dyeing can leverage local renewable fuels to lower fuel bills and CO₂ footprint. ZOZEN Boiler’s SZL/DZL/DHL/SHL series feature wide fuel adaptability and engineered furnace-grate systems to address ash fouling, coking, abrasion, and hopper hot spots. With multi-cyclone, bag filter, or wet scrubber options, emissions can be tailored to local standards.

Q: What makes ZOZEN Boiler a reliable partner for a boiler for dyeing?

A: With 30+ years of manufacturing experience, ZOZEN Boiler combines strict quality management with application-specific engineering. Features include large furnace chambers, membrane water walls, advanced automatic controls, proprietary smoke-box sealing to prevent leakage, and comprehensive safety interlocks. From fuel assessment and thermal balance to delivery, commissioning, operator training, and 24/7 after-sales support, ZOZEN Boiler ensures your boiler for dyeing runs efficiently and reliably.

Q: What’s the fast path to local support in Singapore?

A: Contact Singtech Boiler, ZOZEN Boiler’s authorized local partner in Singapore. Singtech Boiler provides pre-sales consulting, compliance guidance, system design, logistics, turnkey installation and commissioning, operator training, rapid spare parts, and 24/7 service—making it easy to specify, install, and maintain the right boiler for dyeing for your textile operation.