What is a oil/gas fired three pass steam boiler?

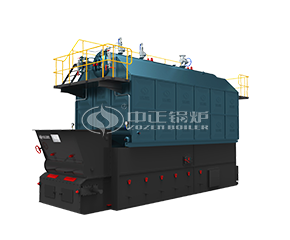

A oil/gas fired three pass steam boiler is a classic industrial boiler design in which combustion gases flow through the boiler drum in three distinct passes before exiting to the atmosphere. This structure ensures maximum heat transfer efficiency. ZOZEN Boiler’s WNS series horizontal internal combustion boiler is a leading example, featuring a shell-type, wet-back, three pass design suitable for various fuels like oil and gas.

How does the oil/gas fired three pass steam boiler work?

In a oil/gas fired three pass steam boiler, fuel is atomized by a burner, creating a torch that fills the full corrugated furnace—this is the first pass, where radiant heat is primarily absorbed. The high-temperature flue gas then converges in the reversal chamber and enters the second pass, which consists of threaded smoke tubes, allowing for convective heat transfer. After further cooling in the front smoke chamber, gases make their third pass through smooth tube bundles before exiting through the economizer and chimney. This design maximizes heat absorption and boosts the boiler’s thermal efficiency.

What are the main features of ZOZEN Boiler’s oil/gas fired three pass steam boiler?

ZOZEN Boiler’s oil/gas fired three pass steam boiler stands out for its:

- Corrugated Furnace: Enhances flue gas disturbance, increases heat transfer, and improves furnace strength and elasticity, reducing thermal expansion stress.

- Threaded Smoke Tubes: Increase the residence time of high-temperature gases, reinforce heat transfer, and improve thermal efficiency.

- Economizer and Condenser: Recover waste heat from flue gases, preheat feed water, lower exhaust temperature, and further increase efficiency.

- High Efficiency: System thermal efficiency can reach over 98%.

- Low Emissions: Optional low-NOx burners keep NOx emissions below 30mg/Nm³.

- Easy Installation: Boiler is delivered as a complete unit, allowing for fast installation and short commissioning times.

- Intelligent Control: Advanced automation with multiple interlock protections, simple operation, and low maintenance rates.

What industries are suited for ZOZEN Boiler’s oil/gas fired three pass steam boiler?

The oil/gas fired three pass steam boiler by ZOZEN Boiler is widely used in industries such as food processing, pharmaceuticals, textiles, building materials, and district heating. Its reliable quality, high efficiency, and environmental performance make it the preferred steam supply solution for many sectors with steam requirements ranging from 1 to 25 tons and pressure from 0.7 to 2MPa.

Why choose a oil/gas fired three pass steam boiler from ZOZEN Boiler?

Choosing a oil/gas fired three pass steam boiler from ZOZEN Boiler means benefiting from proven safety, energy efficiency, environmental protection, durability, and intelligent operation. Factory-assembled design shortens installation time, while the robust structure and advanced combustion technology ensure long-term reliability and low operating costs.

How does the oil/gas fired three pass steam boiler contribute to energy savings and emission reduction?

ZOZEN Boiler’s oil/gas fired three pass steam boiler maximizes fuel utilization through enhanced heat transfer surfaces like corrugated furnaces and threaded smoke tubes, combined with efficient economizers and condensers. The result is a system thermal efficiency exceeding 98%, reduced fuel consumption, and minimized pollutant emissions—making it an ideal choice for enterprises pursuing green, low-carbon production.