- HOME

- PRODUCT

Gas-fired(oil-fired) boilers

WNS Series Gas/Oil Fired Hot Water Boiler SZS Series Gas/Oil Fired Hot Water Boiler ZZ series gas-fired (oil-fired) power plant steam boiler WNS gas-fired (oil-fired) skid-mounted steam boiler

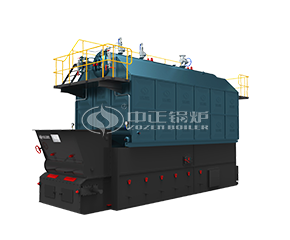

Coal-fired boilers

DZL Series Coal Fired Hot Water Boiler SZL Series Coal Fired Hot water Boiler DHX Series Coal Fired CFB (Circulating Fluidized Bed) Hot Water Boiler SHX Series Coal Fired CFB (Circulating Fluidized Bed) Steam Boiler - APPLICATION

- CASE

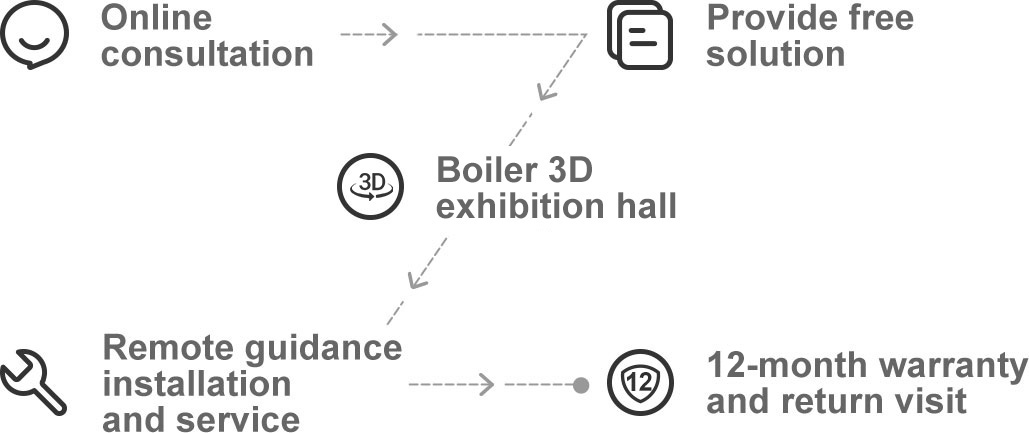

- SERVICE

- NEWS

- ABOUT

- CONTACT

-300x225.jpg)