Case introduction

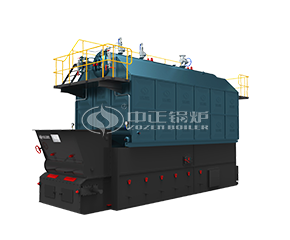

Jiangxi Dadi Pharmaceutical Co., Ltd., a well-established pharmaceutical manufacturer specializing in APIs, TCM preparations, and chemical raw materials, has seen growing energy needs with its expanding operations and advanced production technologies. To promote energy conservation and emission reduction while maintaining high productivity and quality, the company partnered with ZOZEN Boiler and installed a DZL series 15-ton biomass chain grate steam boiler.

With the addition of the ZOZEN boiler, Jiangxi Dadi Pharmaceutical ensures a steady steam supply for its production line, while also achieving high energy efficiency and improved environmental performance:

● High Thermal Efficiency:The thermal efficiency exceeds 87.5% due to a dense water-cooled wall tube design and a customized boiler system, providing ample radiation area and reducing heat loss.

● Flexible Fuel Options:The boiler accommodates various biomass fuels—such as pellets, rice husks, wood chips, corn cobs, and sawdust—helping the company lower operating costs.

● Complete Combustion:Equipped with a chain grate and independent wind chambers, the boiler ensures thorough fuel combustion, minimizing energy waste.

.jpg)