Pakistan, the world’s fourth-largest cotton producer and third-largest consumer, plays a pivotal role in global textiles. With policies supporting technology upgrades and duty-free imports of textile machinery, the country’s textile sector is expanding rapidly—and with it, the demand for high-efficiency, energy-saving boilers.

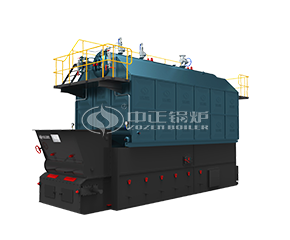

ZOZEN Boiler has partnered with LUCKY TEXTILE MILLS LIMITED (LUCKY TEXTILE) to deploy advanced biomass technology that aligns with the mill’s sustainability goals. At LUCKY TEXTILE’s facility, ZOZEN Boiler has commissioned a 25 t/h biomass reciprocating grate steam boiler, one of the company’s largest biomass installations in Pakistan, based on the DZW25-1.25-SS model.

In markets such as Pakistan where coal costs remain elevated, ZOZEN’s DZW series leverages a reciprocating grate to fully combust diverse biomass fuels, boosting efficiency and output. The 25 t/h biomass reciprocating grate steam boiler offers wide fuel adaptability—straw, wood chips, palm shells, high-moisture and bulk biomass—supporting secure fuel sourcing and stable operations.

Engineered for reliability, ZOZEN increased the furnace height by 1–3 meters to expand the heat-transfer area. As a result, the 25 t/h biomass reciprocating grate steam boiler maintains furnace temperatures below the ash fusion point, mitigating coking, enhancing thermal efficiency, and extending service life.

The tri-drum layout minimizes ash accumulation, while a shock-wave soot blower enables online cleaning without shutdown. For continuous processes in high-quality home textiles—dyeing, drying, sizing, and printing—the 25 t/h biomass reciprocating grate steam boiler delivers steady, low-fluctuation steam that safeguards product quality and throughput.

LUCKY TEXTILE chose ZOZEN Boiler for its proven performance in Pakistan—over 140 ZOZEN units are in operation—reinforced by positive prior experience with ZOZEN coal-fired boilers and an on-site visit to the company’s manufacturing base. SKIC, ZOZEN Boiler’s exclusive agent in Pakistan with more than 30 years of boiler agency experience, provided professional, end-to-end support to complete installation and commissioning in just 30 days.

This collaboration exemplifies how technology and sustainability can reinforce each other in a core manufacturing sector. As the Belt and Road Initiative progresses, ZOZEN Boiler aims to replicate and scale the 25 t/h biomass reciprocating grate steam boiler solution across regional markets, helping more industries cut emissions and enhance efficiency.

ZOZEN Boiler is strengthening its footprint in Singapore through Singtech Boiler, our authorized agent. Singtech Boiler delivers end-to-end, professional support for the 25 t/h biomass reciprocating grate steam boiler and the broader ZOZEN portfolio, including pre-sales consulting and fuel assessment, boiler type recommendation, system planning and cost comparison, local compliance guidance, turnkey installation and commissioning, operator training, and 24/7 after-sales maintenance with reliable spare-parts supply.